Are you interested in knowing more about Dynamics 365 for Finance and Operations? Have a look at the process of sales which can be handled by the system. In this blog post I walk you through the key steps of a sale managed in D365FO and show you the benefits that automation can bring to the company.

This post is also applicable for Dynamics AX 2012 (aka AX2012).

Although D365FO provides functionality for retail, this post is about a wholesaler and employs warehouse management functionality. The process can be applicable for a distribution or manufacturing company.

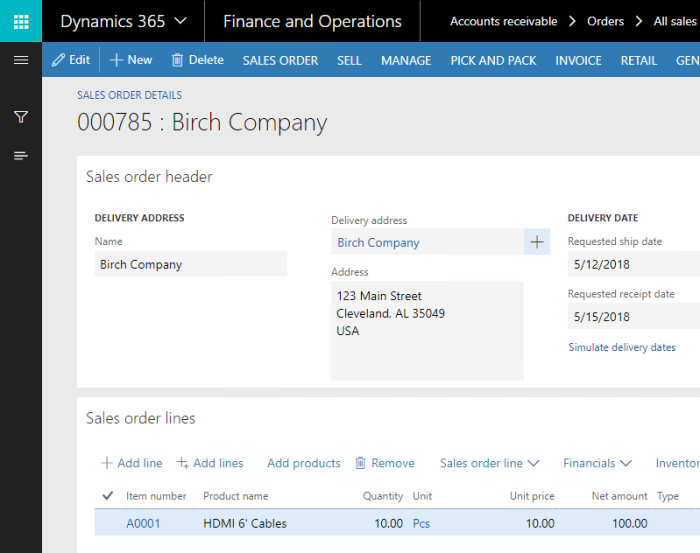

A sale commitment in D365FO starts from recording a sales order to the system. A sales order can be created from a sales quote or a sales representative creates it and inputs information about ordered goods or services to the system. Generally the sales person inputs the data about the customer, the products needed, and quantity. The system can determine the prices and apply discounts, and sets payment method and other parameters by using predetermined master records.

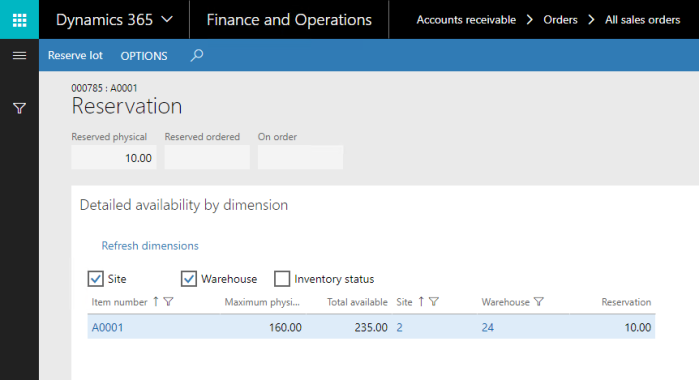

In order to guarantee of fulfilment of the order, the sale representative reserves the inventory for the sale order. Reservations can be done in different ways: automatically or manually, it can be for the exact batch, or on the warehouse level, or on the level of a site. It is even possible to reserve inventory which is not available physically but only ordered from the supplier. Reservation is a strong tool to make sure that a customer will get the goods ordered.

When the order is ready for shipment then outbound logistics comes into play that is picking, packing, loading, and shipment operations. A lot of different options are available in the system to perform these activities. The most straightforward way is to put the sales order directly onto the load.

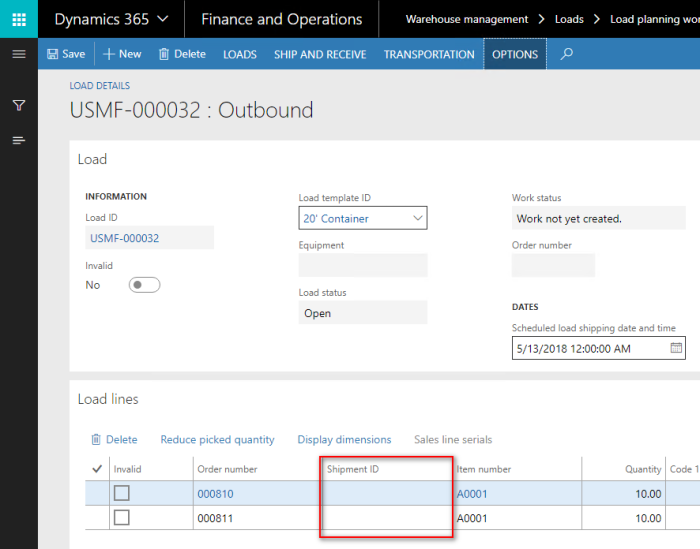

The load in D365FO can be associated with a transportation unit, for example with a truck or a container. Security seals are linked to the load. Also, a dock appointment can be managed for the load.

The sales order can be included in the load by someone who is in charge of delivery of ordered goods, for example a warehouse supervisor. The “load planning workbench” page is used for managing loads.

A huge sales order can be split into many loads if many trucks are needed to deliver the order. On the other hand, a lot of sales orders can be put into the same load if many sales can be delivered by a single truck. Let’s consider when a few sales orders are loaded onto a single truck. In this case, the “load details” page contains many lines, one line per order.

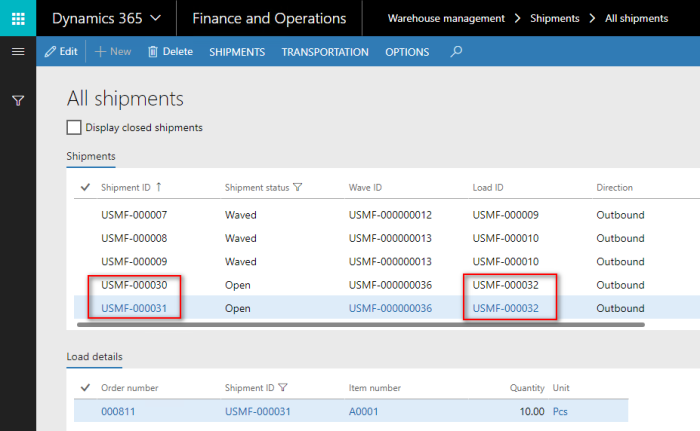

When the load is formed and the truck is ready for loading, the load is released to the warehouse. The release of the load creates shipments for each sales order.

A shipment is a package of things which are delivered to the same destination address. The bill of lading is linked to the shipment. The shipment can include many sales orders which are going to the same destination.

More accurate planning of loading of trucks can increase utilization and efficiency of vehicles. The planning of loads should be less time consuming as the software helps to do it in a more efficient way. More accurate appointments planning should positively contribute to the efficiency of bay doors usage. Efficient usage of the facilities always leads to cost optimization.

The release of the load to the warehouse creates a wave. The wave contains the list of works that need to be performed in order to load the truck.

D365FO offers many options for organizing a work creation process. For example, the work can include lines for picking goods from the storage location and putting them directly to the truck. Another option is to take goods from the storage location and put them in the staging area. After that when the truck comes to the loading dock, the goods should be taken from the staging area and put on the truck.

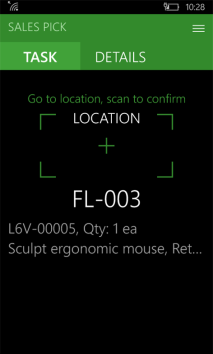

The warehouse worker uses the mobile device to execute the works: pick the goods and put them to the truck. Warehouse worker follows the instructions shown on the mobile device. The system can inform the warehouse worker where exactly and how many goods to pick and where to put them. The worker can fulfil many orders simultaneously. As a result it decreases effort needed to fulfil orders.

When the load is completed, the warehouse supervisor registers that load is done. It means that a loaded shipment is on its way to the customers. After that the invoice can be issued for the quantity shipped.

This post covers only one example of implementing of a sales process. There can be a lot of variations as D365FO is very flexible and can be tuned precisely to the business needs. The system helps to improve a sale process dramatically, and makes it more straightforward, more robust, more efficient, and more effective. This leads to advanced customer service and decreases the operation cost. In turn, that positively contributes to the profit of the company.

Also, thinking about the future, the system can be a foundation for advanced automation. People at the warehouse follow the instructions on the mobile device today, but imagine what can be tomorrow. The system can give commands directly to robots instead of people. Who knows when they will become a part of our life?